Disposal of EcoBeans

EcoBeans are made solely from Polylactic Acid (PLA) with no nasty additives. There are a number of potential disposal options for PLA, including industrial composting, incineration and, where infrastructure is available, recycling.

If available, industrial composting is an excellent disposal option. For composting to occur the right combination of moisture, heat and micro-organisms is required. The description and diagram below from the Natureworks (manufacturers of the PLA brand Ingeo) website describe the process. Click on Ingeo Composting to visit their webpage. Currently we utilise the raw material, Ingeo PLA resin to produce EcoBeans. Check out NZ composters The Brothers Green composting video on Facebook.

How Composting PLA Works

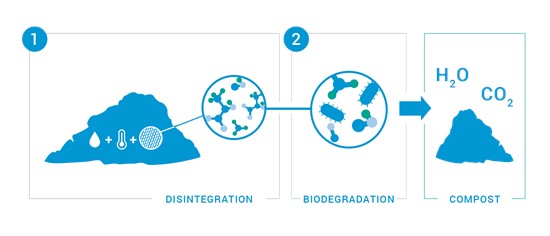

Ingeo biopolymer is made primarily of polylactic acid (PLA), a repeating chain of lactic acid, which undergoes a 2-step degradation process.

1. DISINTEGRATION: The moisture and heat in the compost pile split the polymer chains apart, creating smaller polymers, and finally, lactic acid.

2. BIODEGRADATION: Microorganisms in compost and soil consume the smaller polymer fragments and lactic acid as nutrients. Since lactic acid is widely found in nature, a large number of organisms metabolize lactic acid.

The end result of composting is carbon dioxide, water and humus, a soil nutrient. This degradation process is temperature and humidity dependent.

While there are a number of composting facilities throughout New Zealand, composting of PLA is still relatively new and infrastructure for this is limited. We are working with some of these facilities to get EcoBeans accredited and accepted for composting. To ensure that EcoBeans are correctly disposed of, we will, where possible, take back your old EcoBeans, although they must be clean and not contaminated with other materials such as polystyrene. Please contact us if you need to dispose of your EcoBeans.

We recently ran a trial at a commercial composting facility. They placed the EcoBeans into their normal composting process. After 3 weeks the material was turned over and the EcoBeans were degrading nicely. After a further 3 weeks EcoBeans had composted to become invisible to the naked eye.

See below for information on European and Australian Industrial Composting Standards

The criteria for the industrial compostability of packaging are set out in the European standard EN 13432. EN 13432 requires the compostable plastics to disintegrate after 12 weeks and completely biodegrade after six months. That means that 90 percent or more of the plastic material will have been converted to CO

2.

The Australian standard AS 4736-2006 provides assessment criteria for plastic materials that are to be biodegraded in municipal and industrial aerobic composting facilities. This Australian standard is similar to the widely known European EN 13432 standard, but has an additional requirement of a worm test. In order to comply with the AS 4736-2006, plastic materials need to meet the following requirements:

·minimum of 90% biodegradation of plastic materials within 180 days in compost

·minimum of 90% of plastic materials should disintegrate into less than 2mm pieces in compost within 12 weeks

·no toxic effect of the resulting compost on plants and earthworms.

·hazardous substances such as heavy metals should not be present above the maximum allowed levels

·plastic materials should contain more than 50% organic materials.

Click on the links below for more information on Industrial Compostability Testing at Scion, a certified biodegradation facility

Industrial Compostability Testing.pdf

Scion Compostability testing infosheet.pdf

Where other options such as composting are unavailable, one end-of-life option used globally is incineration. Analysis by Natureworks (PLA manufacturers) shows that no volatiles and low residues are produced when incinerating PLA resin. Click on Ingeo Incineration to visit their webpage.